How To Square Up Stock In A CNC Milling Machine

Using Square stock allows you to create parts that mate well together. It is impossible to repeatedly create parts without starting from squared up stock. Since one of the reasons we use CNC milling machines is to create multiples identical parts, it only makes sense to start with squared up stock.

- Use the fixed jaw of the vise as the reference surface

- Machine the largest side of the stock first.

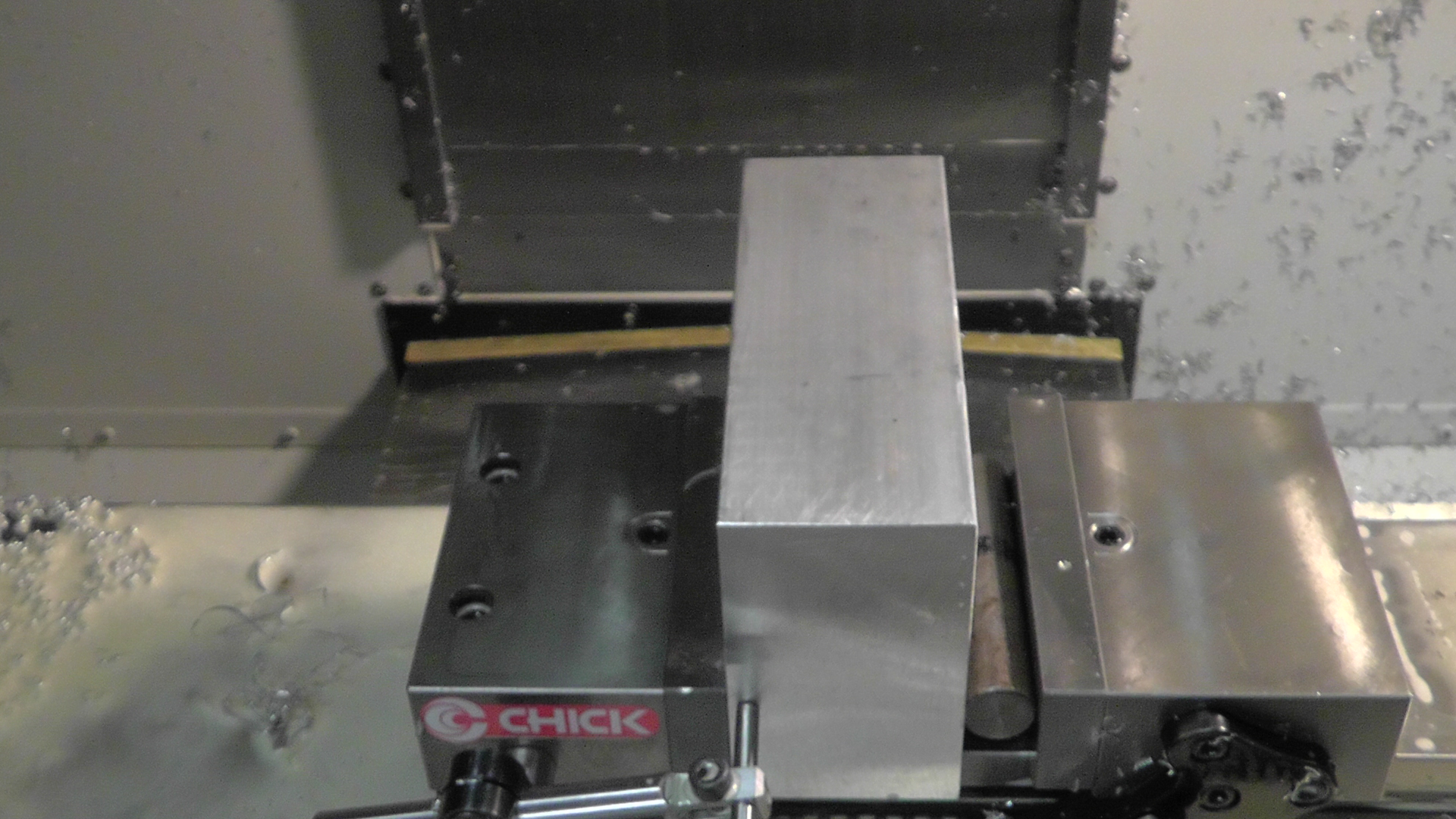

- Use an aide to guarantee sides are flush with vise

- Debur each side between cuts

- Clean the vise jaws between cuts.

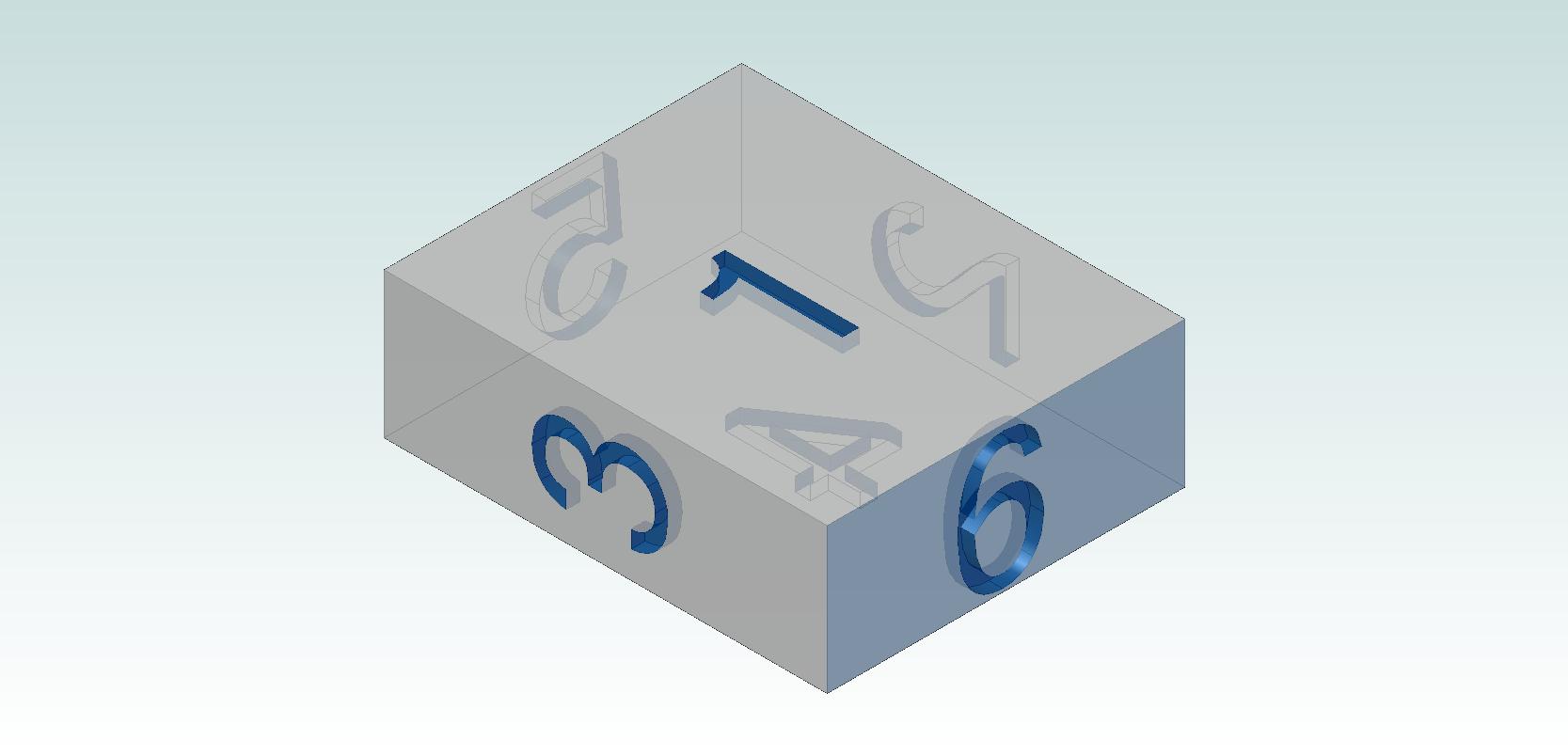

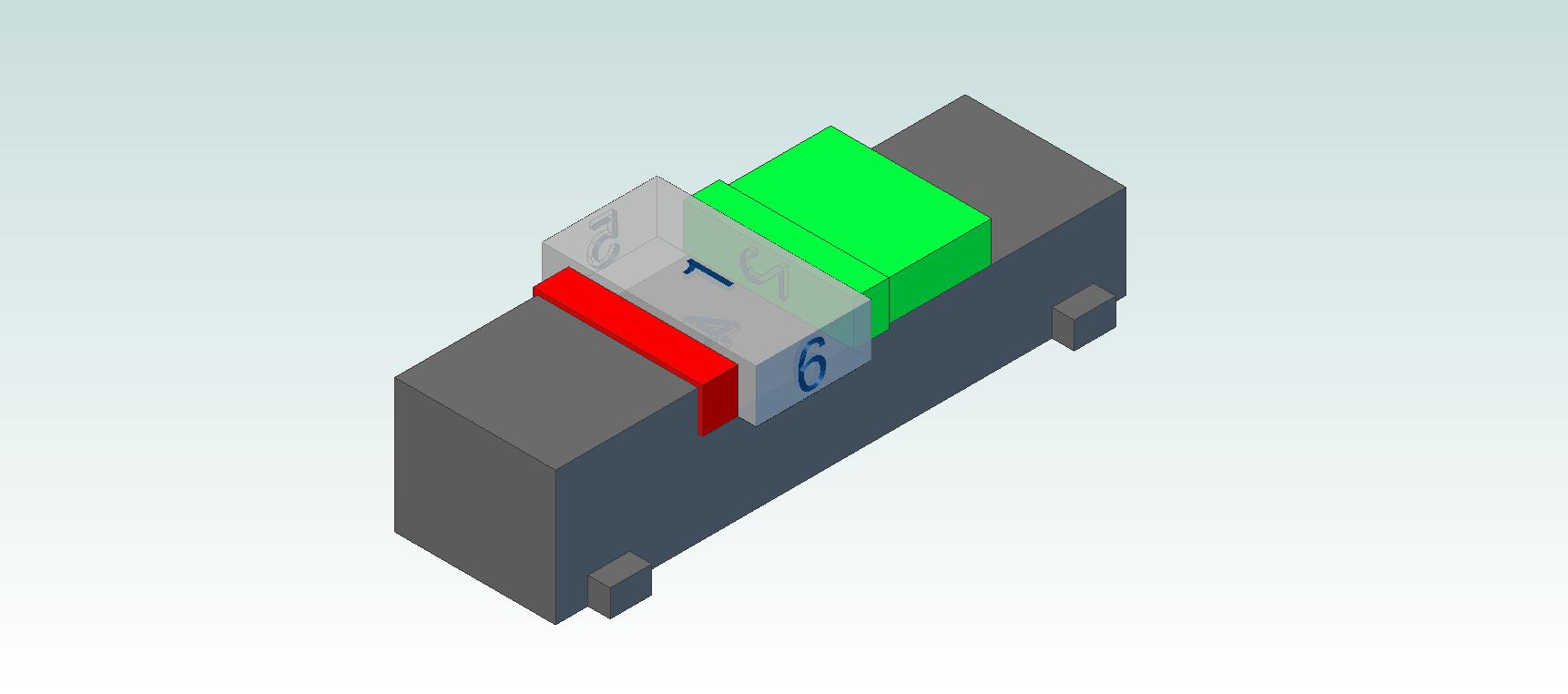

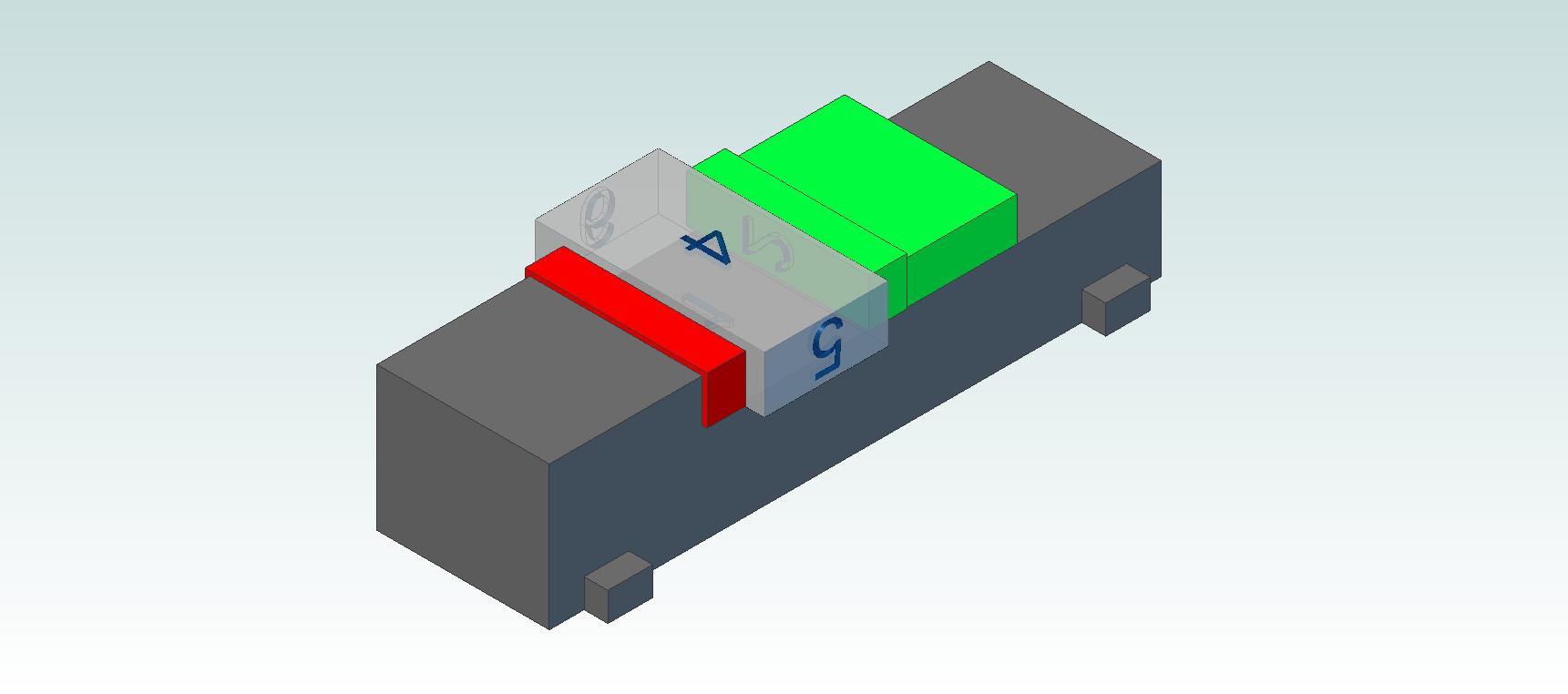

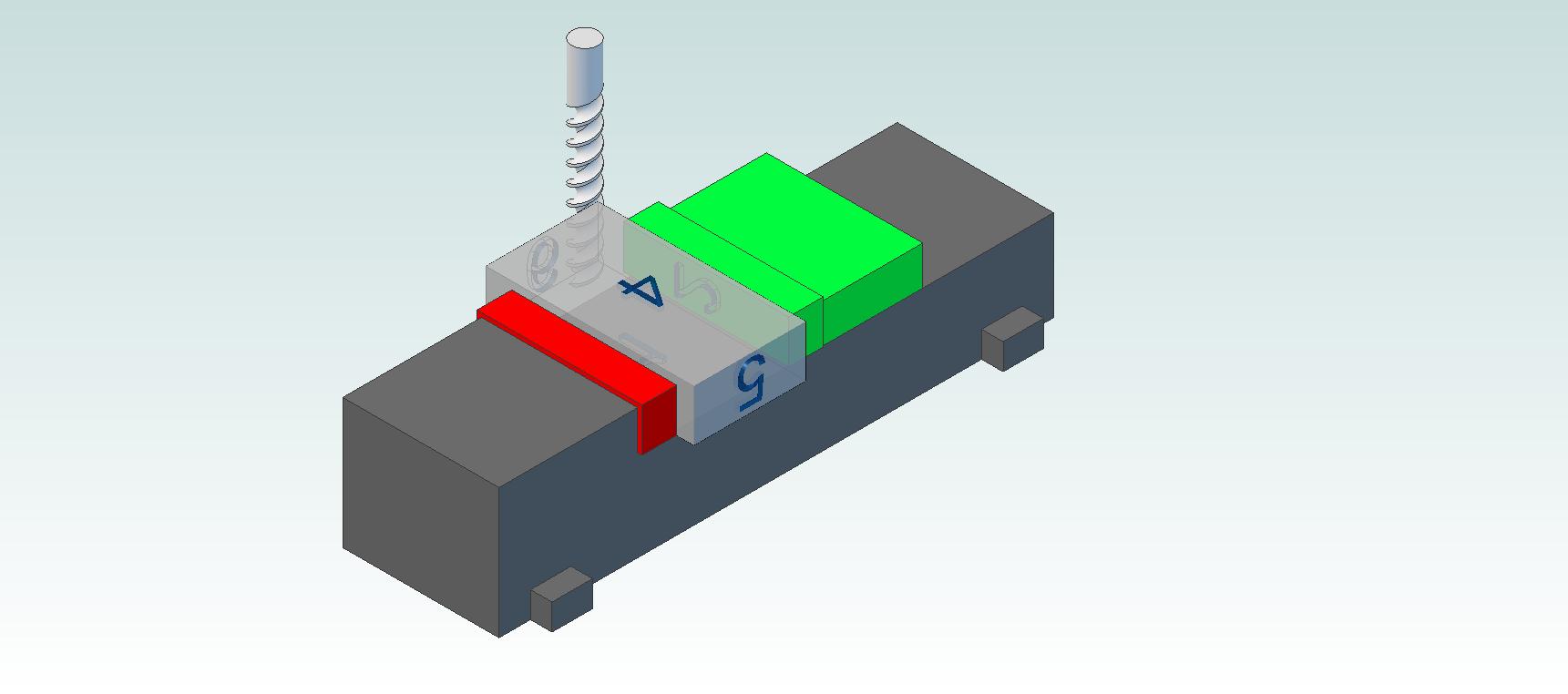

Number your stock

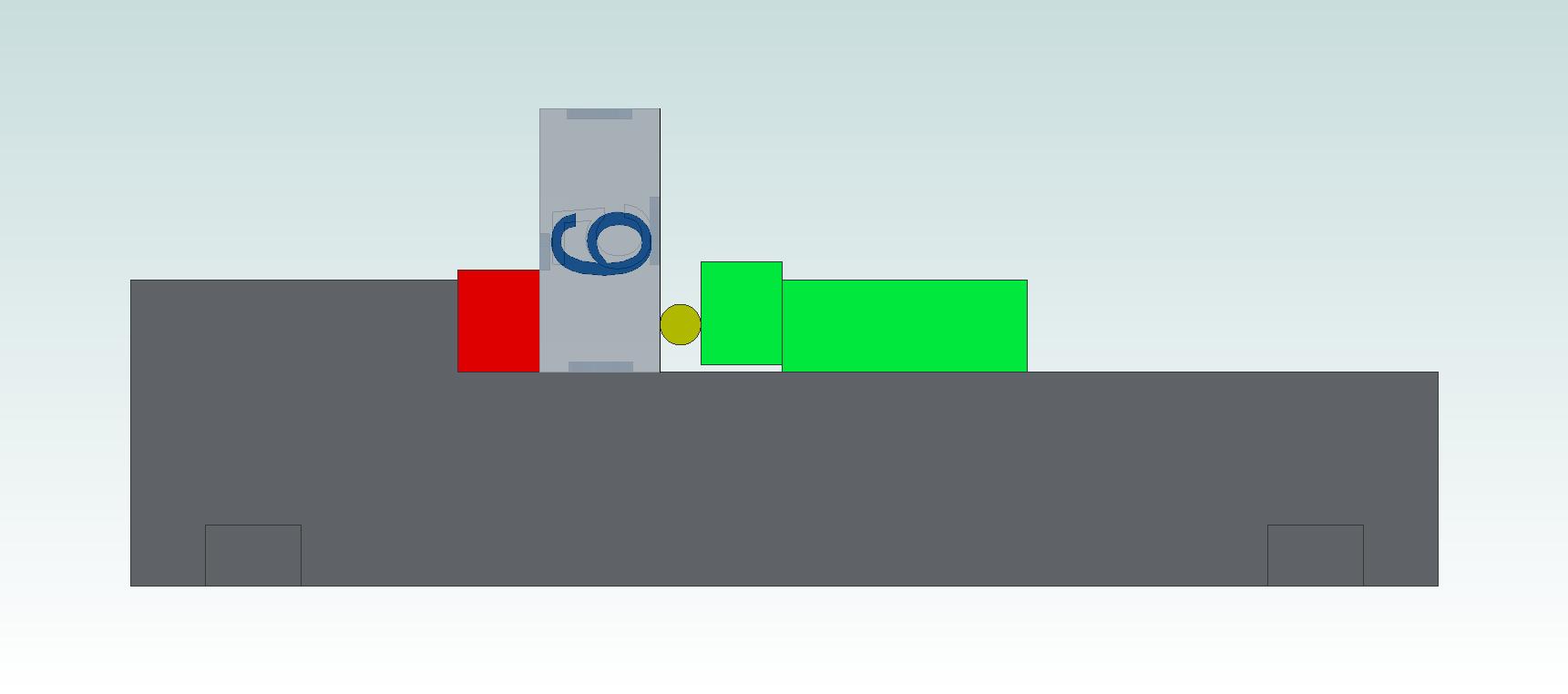

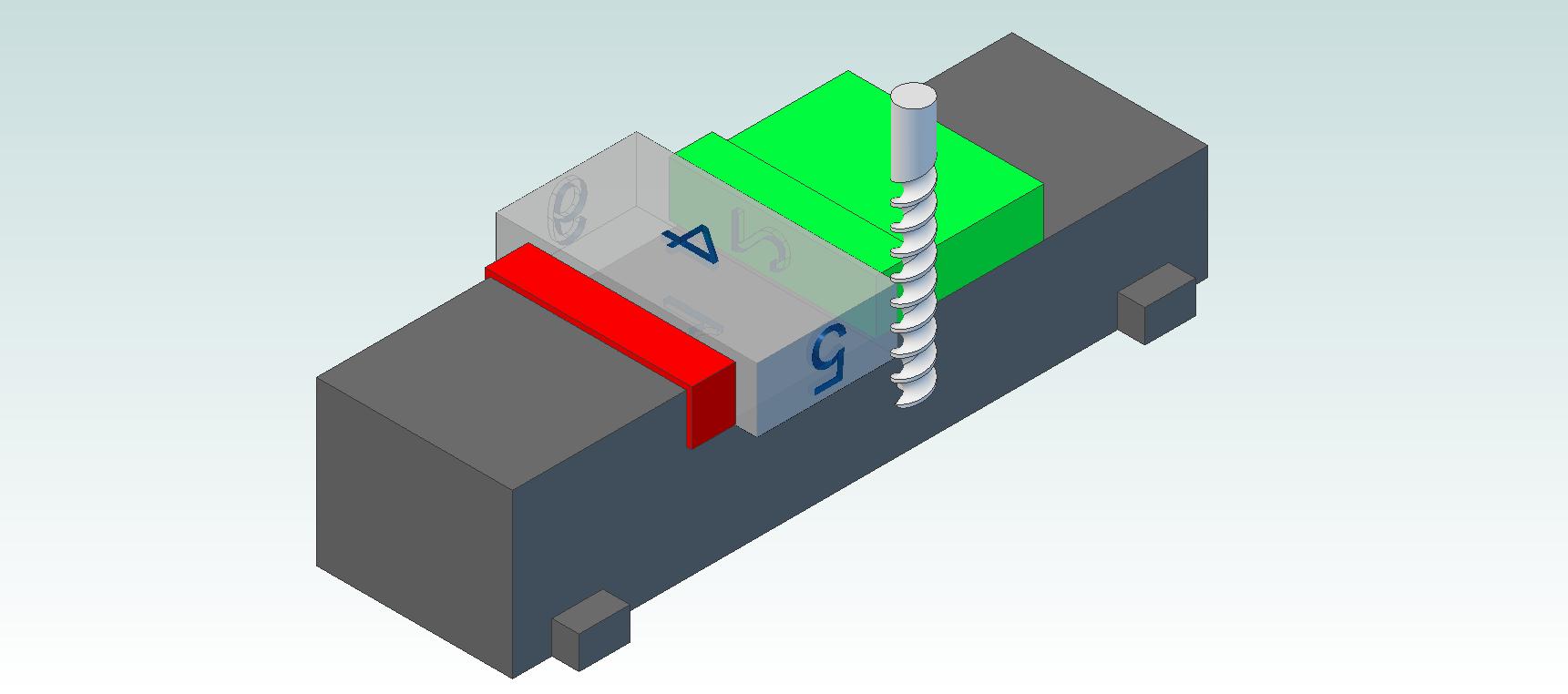

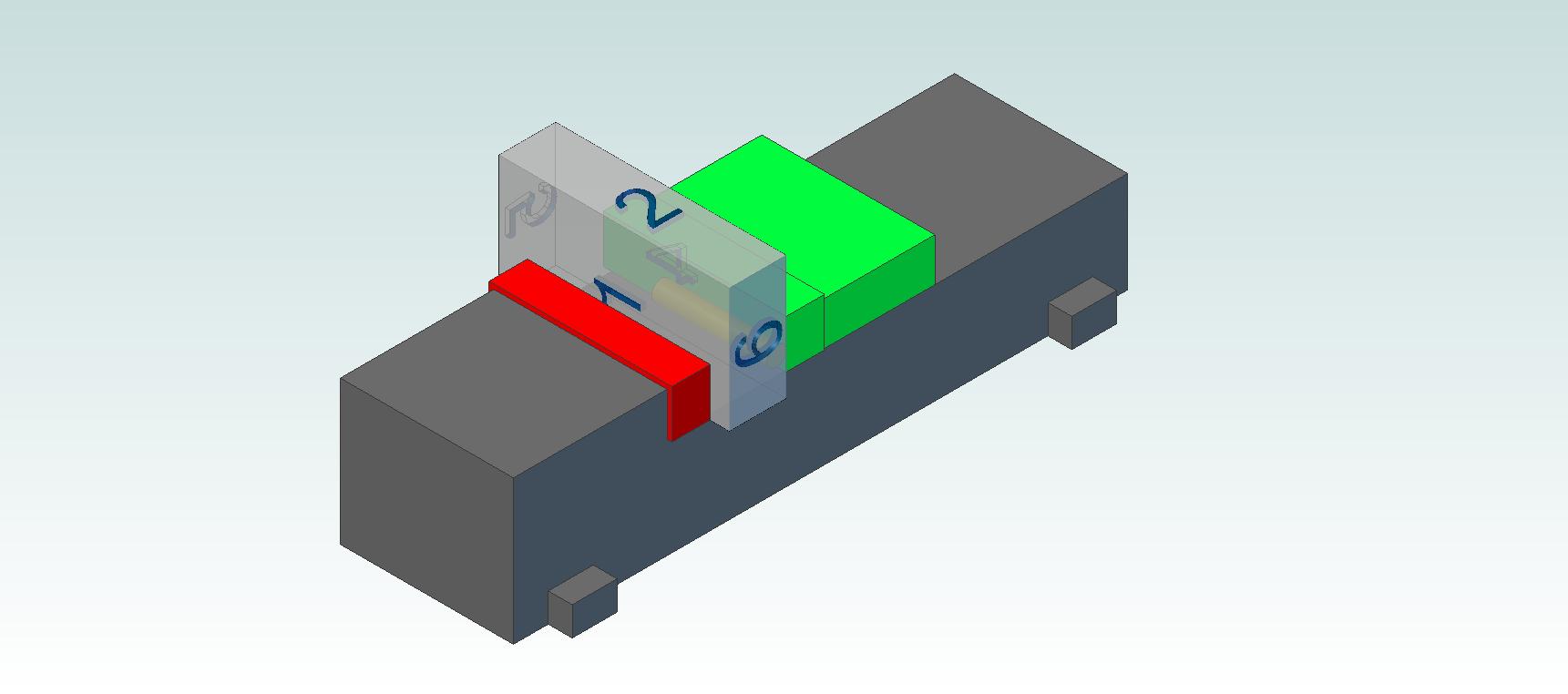

Add Spacer

A piece of round stock is placed in the vise between the movable jaw and the stock. The round stock forces the machined edge flat against the vise jaw.

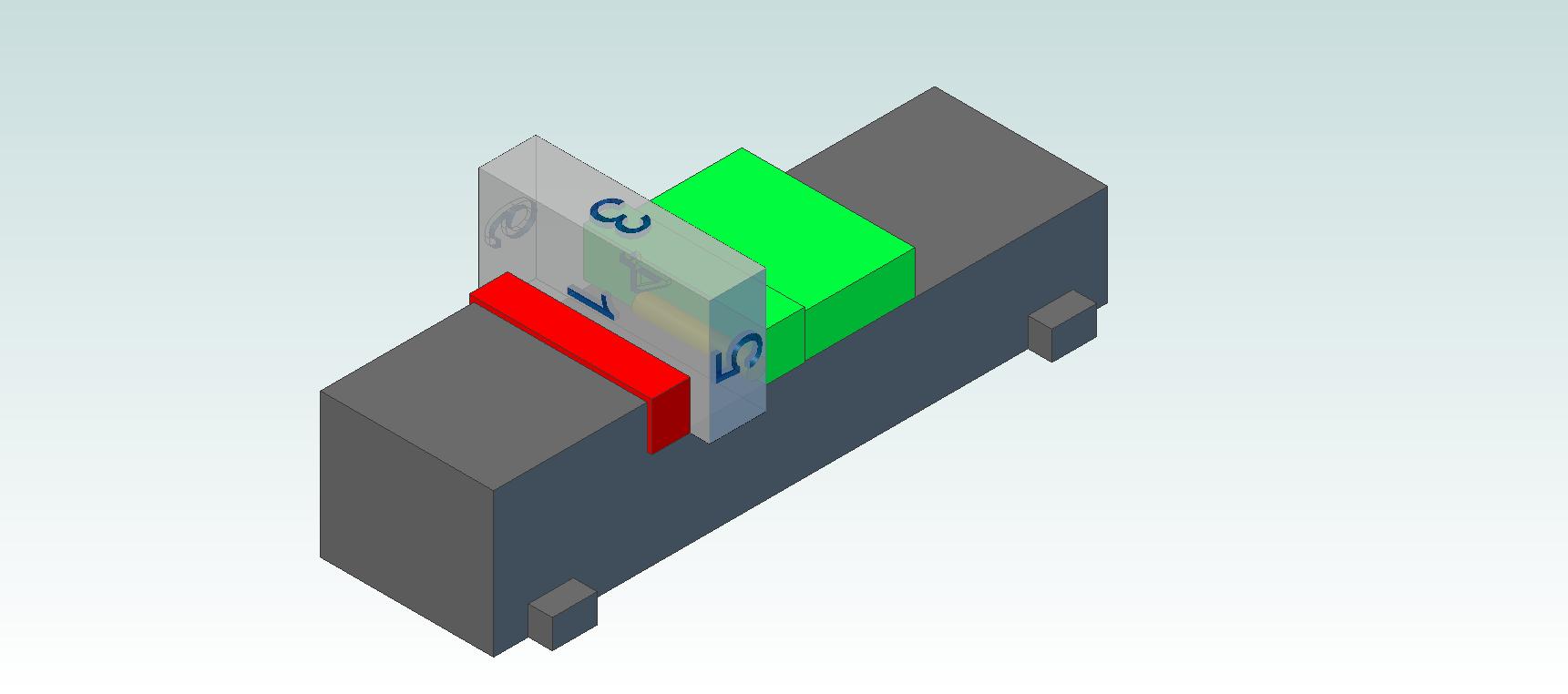

SIDE THREE

Place the round stock back in the vise between the movable jaw and touching side 4. Tighten the vise.

Machine side 3 flat. Deburr the edges.

You now have two sides parallel to each other. Both sides are perpendicular to side 1.

SIDE FIVE

Side One

SIDE TWO

We now have two sides which are machined 90 degrees in relation to (perpendicular) each other.

SIDE FOUR

Machine side 4 and then deburr the edges.

SIDE SIX

Deburr the edges you haven’t deburred yet.

All six sides are now machined square .